Why do car engines have high - temperature nylon

Why do car engines have high - temperature nylon

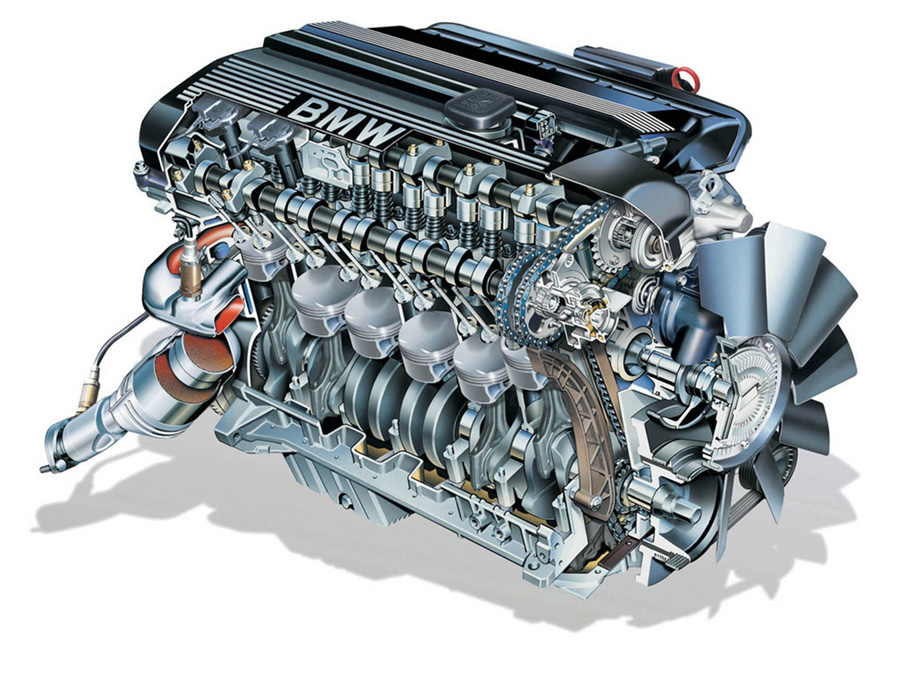

High-temperature nylon is widely used in automobile industry due to its superior mechanical strength, dimensional stability, chemical resistance and ultra-high thermal aging performance. It is mainly used in automobile cylinder cover, thermostatic shell, engine cover and other engine peripheral products.

Due to its superior mechanical strength,dimension stability, chemical resistance and anti-heat aging properties, highheat polyamide has become a favorite in the automotive industry. Cylindercovers, thermostat housings, engine parts and covers, etc. are some of theapplications of PPA in vehicles.

In the end of last century, the plasticization of electronic, motor and automobile parts made higher demands on nylon performance and high temperature resistance.In 1990, DSM first industrialized high-temperature nylon (PA46), filling the gap between general engineering plastics (such as polyamide 6, polyamide 66, polyester) and ultra-high performance materials (such as LCP, polysulfone and PEEK), thus kicking off the development and application of high-temperature nylon.

High-flowing glass fiber reinforced high-temperature nylon PPA is one of the new products that attracts people's attention. It is also one of the fastest developing and most cost-effective new materials.The glass fiber reinforced high temperature nylon composite material based on high-temperature nylon PPA is easy to produce high-precision high-temperature high-strength products.Especially for automobile engine peripheral products, it is necessary to cope with the increasingly harsh aging requirements. High-temperature nylon has gradually become the best choice for automobile engine peripheral materials.What's unique about high-temperature nylon?

Excellent mechanical strength

High-temperature nylon with traditional aliphatic polyamide (PA6 / PA66) compared with the obvious advantages, mainly reflected in the basic mechanical properties of product and its heat resistance performance, from the basic mechanical strength compared to high temperature under the premise of nylon, under the same glass fiber content, 20% higher than the traditional aliphatic polyamide, can provide more lightweight solution for cars.For example, 30% of PPA GF stretching can achieve 230MPa, while the tensile strength of traditional aliphatic nylon is 190MPa.

Extremely high thermal aging performance

For the thermal deformation temperature under the premise of 1.82 MPa, 280 ℃ high temperature nylon 30% glass fiber reinforced, while traditional aliphatic PA66 GF probably 30% at 255 ℃.Although aliphatic nylon through modification can improve the thermal aging properties of materials, but when the requirements of the product increased to 200 ℃, the traditional aliphatic nylon is hard to meet the requirements of products, especially the engine peripheral products under high temperature and high humidity environment over a long period, and will bear the corrosion of mechanical oil, high temperature and nylon its special structure of benzene ring given its high temperature resistant characteristics.

Excellent dimensional stability

Traditional aliphatic polyamide due to the high proportion amide groups, therefore, aliphatic nylon bibulous rate is higher, saturated water absorption can reach 5%, leading to the size of the product stability is very low, for some is not suitable for high precision products, and high temperature reduced the proportion of amide groups in nylon, bibulous rate is half of the normal aliphatic polyamide, dimension stability is superior.

Excellent chemical resistance

Because the car engine peripheral products often want to contact with chemical reagents, so the chemical resistance of the material are put forward higher request, especially gasoline, frozen liquid chemicals such as caustic corrosion of aliphatic polyamide has obvious effect, and high temperature nylon special chemical structure to make up for the shortcomings, the presence of high temperature nylon makes the engine using the environment up a class again.

Automotive application

Because of PPA can provide more than 270 ℃ heat distortion temperature, so it is a suitable for cars, heat-resistant parts in mechanical, electrical/electronic industry ideal engineering plastics.PPA is also ideal for those parts where structural integrity must be maintained at short temperatures.

Taking the application of automobile industry as an example, heat-resistant plastics are rapidly replacing traditional engineering plastics due to the requirements of automobile industry to improve safety, comfort and motor management, to require longer service life and service life, and to solve the problem of excessive temperature in the engine area.

In particular, the solution to environmental problems such as the reduction of CO2 emissions and the improvement of fuel consumption in the automobile industry is to increase the combustion temperature of the engine and make the fuel fully burnt. In this way, it is bound to increase the engine room temperature and raise the heat resistance requirements of all plastic materials.

Meanwhile, the plasticization of metal parts such as fuel system, exhaust system and cooling system near the engine has been replaced by the thermosetting resin for recycling.The heat resistance, durability and drug resistance of the former general engineering plastics have not met the requirements.

In addition, the high-temperature nylon series maintains the well-known advantages of plastics, namely easy to process and trim, easy to realize the free design of complex functional integrated parts, and can reduce weight, noise and corrosion resistance.

Due to the high temperature nylon can withstand high strength, high load, high temperature and other harsh environments, it is very suitable for the application of the engine area (such as engine cover, switch and connector), transmission system (such as bearing retainer), air system (such as exhaust control system) and intake device.

In conclusion, the excellent properties of high-temperature nylon can bring a lot of benefits to users, and the conversion from PA6, PA66 or PET/PBT to PPA does not require modification of the mold, etc. Therefore, it has a broad prospect in various applications requiring high temperature resistance.

Development status of high-temperature nylon industrial chain in China

According to foreign market reports, China's demand for nylon mixtures reached 89.45 million tons in 2012 and is expected to grow by 7.5 percent in the next five years.That would require 1.3 million tons of nylon mixtures to be available on the market in 2017.In 2014, the domestic demand of high-temperature nylon was about 70,000 tons, and the global demand was about 200,000 tons, and the trend of steady growth has been maintained.

The market demand can promote the development of an industry. Only when there is demand can there be the power of production, which leads to fierce competition and promotes the progress of the industry.At present, domestic enterprises engaged in high-temperature nylon mainly include goldilocks technology co., ltd. and polymer research institute. The high-temperature nylon developed and produced by them is PA10T, which is widely used in the industries of electronics, lighting, corrosion prevention, water heating, nuclear power and vehicles.

In addition to meeting the needs of domestic customers, goldilocks technology's high-temperature nylon products are also exported in bulk.To meet the growing market demand, goldilocks is building a new PA10T project with an annual capacity of 3,000 tons. Production is expected to start in the second half of 2017, when the total annual capacity of high-temperature nylon will reach 8,000 tons.

In addition, the PPA series produced by shenzhen hualixing new materials co., ltd. also fills the gap of domestic high-temperature nylon composites.China's high-temperature nylon market is very broad and has considerable development prospects in the future, but the market share of domestic products is not very high, mainly due to technical barriers and brand building.As a local enterprise, in the future development should be committed to the development of new product performance and other areas of development.

- Last:Keep up with the tide!Four major modification trends of engineering plastics are promising 2018/6/29

- Next:What new applications of medic 2018/6/29